Food industry experts know that getting products from the production line to store shelves is not as simple as it looks. You are not just mixing ingredients and sealing bags. You have to deal with strict safety rules, fast-moving machinery, changing product types and customers who expect perfect quality every single time. Weighing and packaging may look like a small part of the entire process, but in reality, these challenges in the food industry can make or break profit margins.

Underfilling packages can get a company into legal trouble and overfilling means giving away product for free. Packaging mistakes can lead to damaged goods, unhappy retailers, and wasted inventory. This is why so many manufacturers are now relying on advanced technologies such as a Multi-Head Combination Weigher or a Multi-Head Combination Scale to solve these long-standing issues.

Let us break down the most common weighing and packaging challenges in the food industry and how the right equipment can help solve them.

1. Inconsistent Product Weights

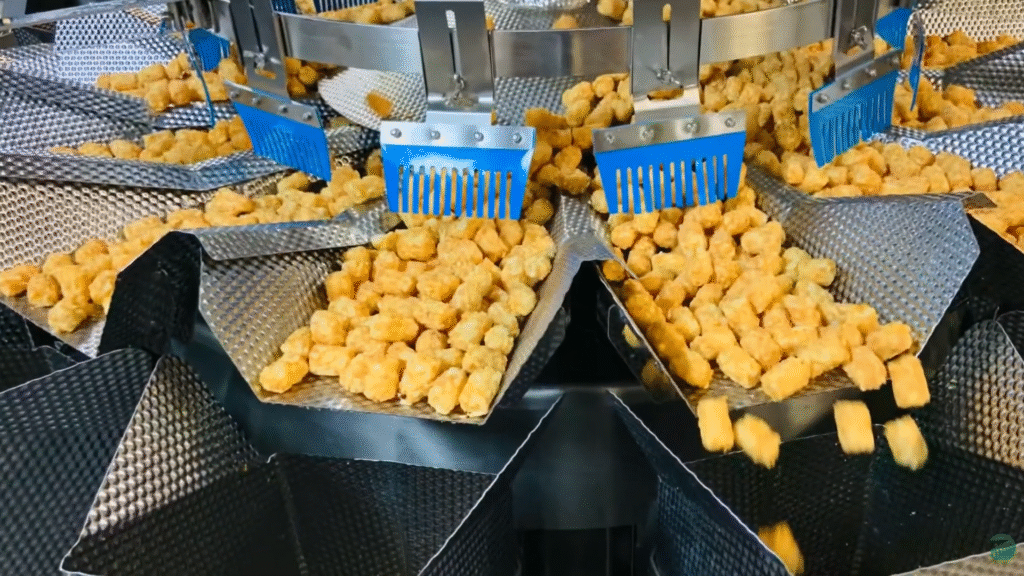

When workers weigh products manually there is always a risk for human error. Two bags that are supposed to weigh exactly the same may end up with slightly different weights. In food manufacturing, where every gram counts, a Multi-head Combination Scale solves this issue. Using multiple weighing heads to calculate the precise weight before the product hits the packaging line, it works with accuracy that humans simply cannot match. That means every package is the correct weight, protecting the brand’s image and keeping retailers happy.

2. Product Damage During Packaging

Think about fragile foods like (chips, crackers, candies, cookies, dried fruit, or even soft produce). When the wrong equipment is used, the product can be damaged before it reaches the customer. Traditional weighing systems often cause hard-drops or rough handling which leads to broken products and wasted inventory.

A Multi-Head Combination Scale handles products gently which reduces breakage. It also controls how the product flows, how it is portioned, and how it is inserted into the packaging. Companies that switch to modern weighing systems have less waste and far fewer damaged goods which increases profits.

3. Slow Production Speeds

Growing production demand cannot be met when machines are slow. With manufacturers facing backups and delayed shipping, customers become frustrated and companies lose money due to inefficient packaging production lines.

High Tek Food Packaging and Weighing Equipment is designed to solve weighing and packaging challenges in the food industry by keeping your production line fast and reliable. A Multi-head Combination Weigher can process large volumes of product within minutes and can run continuously without needing breaks. This is one of the biggest reasons factories choose to automate. Faster production means more output, shorter lead times, and fewer staffing issues.

4. Difficulty Handling Different Types of Products

Food manufacturers often produce more than one item. Products can differ in texture; some might be sticky while others are lightweight and varying in size. Switching equipment or adjusting processes manually takes time and often causes errors.

Modern Food Packaging and Weighing Equipment solves this problem with flexible software and settings. A Multi-head Combination Scale can adapt to different food textures and shapes with only a few adjustments. Instead of slowing down production, the equipment allows companies to switch products quickly while still keeping accuracy and speed.

5. Compliance and Food Safety

The food industry has some of the strictest regulations, and for good reason. Every piece of equipment must be hygienic, easy to clean, and built to avoid contamination. A mistake in handling or packaging can lead to recalls, lawsuits, or safety issues.

Well-designed Food Packaging and Weighing Equipment is created with stainless steel surfaces, smooth edges, and easy-to-wash components. There are fewer places for bacteria to hide, and cleaning can be done faster without shutting down the line for long periods of time. Automation also reduces direct human contact with food making the entire process safer and more sanitary.

The Industry Is Moving Forward

Walk into any modern food processing plant and you will find smart machines, sensors, and software doing the work that used to take entire teams. The goal is not just automation for convenience. It is about protecting product quality, staying competitive in a growing market, and meeting strict food regulations.

Food Packaging and Weighing Equipment has become the backbone of this improvement. Manufacturers who use outdated systems are slowly being left behind, while those who invest in technology see faster output, better accuracy, and higher customer satisfaction.

Final Thoughts

Every food company wants accurate weights, clean packaging, zero waste and a satisfied customer. With advanced technology like a High Tek Multi-Head Combination Weigher, these goals are much easier to reach. Whether your company produces snacks, frozen or health foods, using modern weighing equipment brings consistency to every single package.

If the future of food manufacturing depends on speed, precision, and safety, then automation will be the way forward. Companies that embrace new Food Packaging and Weighing Equipment will continue to grow, while the industry moves toward smarter and more efficient operations. Contact the experts here if you are ready to be smart and efficient.