Zoroco and Partake Foods: Partnership in Every Bite

How a family-run Idaho CM/CP and its fast-growing gluten-free cookie brand customer transformed their relationship through automation and a multi-head combination weigher.

If you're still hand-weighing flower, manually filling jars, or dealing with inconsistent package weights, you're leaving serious money on the table. In the competitive cannabis industry where margins matter and compliance is non-negotiable, automation isn't just a luxury anymore but a necessity. Don’t worry, transforming your cannabis packaging line into a fully automated system is more accessible than you might think. Let’s discuss how to make it happen.

Upgrade to Automated Cannabis Weighing and Packaging Systems

Your weighing station is the heart of your operation and is where automation delivers the biggest impact. Manual weighing is slow and inconsistent that leaves you vulnerable to compliance issues. One distracted budtender can create hundreds of underweight packages that cost you product or overweight packages that eat into your margins.

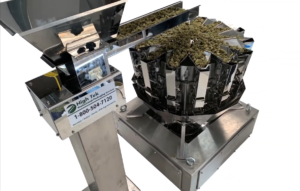

Modern cannabis weighing equipment can achieve 0.01g load cell accuracy and dispense up to 60 batches per minute of 1-to-28-gram variable target weights. Think about the ability for 60 perfectly weighted packages every minute, all meeting regulatory requirements without question.

For packaging flower this is a game changer. For pre-rolls, edibles, or concentrates, it's equally game-changing. Automated weighing and filling equipment ensures accurate dosing as well as compliance with weight regulations all while maintaining the delicate integrity of cannabis products during packaging processes.

Integrate an Automated Capper Machine

Once your product is weighed and, in the container, you need to seal it quickly and consistently. This is where an automated capper machine becomes essential, especially if you're packaging flower in jars or concentrates in containers.

High Tek Automatic cappers ensure caps are precisely applied in every cycle, eliminating product leakage or contamination risks while maintaining high product quality standards. In cannabis, where product freshness and potency preservation matter, proper sealing isn't optional.

Automated capper machines can handle between 20 to 180 bottles per minute with options for multiple capping stations. They’re compatible with various cap types, including twist-off, screw, push-on, snap-on, and child-resistant closures. Child-resistant compliance is crucial in cannabis, and automated cappers ensure every single container meets CR certification requirements. This is an area where manual operations struggle.

Create a Seamless Conveyor System

With the above steps in place, it’s now time to connect them all. Automatic capping machines are typically part of a complete packaging system, including conveyors and any other equipment necessary to prepare a product for the consumer.

Your conveyor system is the highway that keeps product moving smoothly between stations. Buffer zones between machines prevent bottlenecks. If your capper runs faster than your weigher, you need space for containers to accumulate without causing backups or requiring manual intervention.

Some operations use indexing tables at workstations where human oversight is still needed; quality checks, visual inspections, or inserting humidity packs. The key is minimizing manual touchpoints while maintaining quality control.

Invest in Smart Controls and Data Systems

Modern cannabis weighing and packaging automation isn't just about mechanical movement, it's also about building in intelligence. Industry 4.0-ready packaging machines come equipped with remote support capabilities, live stats, and performance analysis.

This means real-time visibility into production rates, waste percentages, equipment performance, and compliance metrics. You can identify which strains package most efficiently, which package sizes have the highest throughput, and where bottlenecks occur.

For multi-state operators, this data becomes invaluable. You can compare facility performance, identify best practices, and standardize processes across locations.

The ROI Is Undeniable

Let's talk numbers because they're impressive. Initial investment in cannabis weighing and packaging automation typically ranges from $50,000 to $200,000+ depending on scale and sophistication. That sounds like a lot until you run the math.

If automation lets you triple your output with one-third of the labor, you're looking at payback periods of 6-18 months for most operations. Add in reduced product giveaway (which can be 5-10% in manual operations), fewer compliance issues, and lower worker's compensation costs, and the ROI becomes even clearer.

Automated systems significantly reduce labor costs while increasing throughput, allowing cannabis businesses to scale production to meet growing demand without proportionally increasing staffing.

Start Your Automation Journey Today

You don't have to automate everything at once. Start with your biggest pain point, which usually is weighing and packaging, and build from there. Work with equipment suppliers who understand cannabis-specific challenges like product stickiness, varying moisture content, and regulatory requirements.

The cannabis industry is maturing rapidly. The operators who embrace automation now will dominate their markets tomorrow. Those who stick with manual processes will struggle to compete on price, consistency, and scale.

It’s about time to assess your current throughput, identify bottlenecks, and get quotes from reputable cannabis packaging automation suppliers. If your competitors are already automating, will you be able to afford not to? Contact packaging automation specialists today by calling 800.504.7120 and discover how cannabis weighing and packaging technology can revolutionize your operation.