Running a food business has never been more challenging—or more exciting. On one hand, the demand for fresh, packaged, and processed food continues to grow. On the other, rising labor costs, worker shortages, and the need for consistent quality make it harder for businesses to scale. If you’ve been relying heavily on manual processes in your production line, you’ve probably already seen how difficult it can be to maintain efficiency. That’s where Automated Food Weighing and Packaging Machine comes in. These systems are transforming the way food businesses operate by reducing dependency on manual labor while improving accuracy, efficiency, and compliance. For companies looking to stay competitive, automation is no longer a luxury—it’s a necessity.

The Labor Challenge in the Food Industry

Across the United States, food businesses are feeling the pinch of a shrinking labor pool. Hiring skilled workers for repetitive tasks like weighing, portioning, and packaging has become increasingly difficult. Even when workers are available, turnover rates can be high, and training takes time and money.

Manual operations also leave room for human error. Overfilled packages mean wasted product as well as lost profits, while underfilled packages risk customer complaints or compliance violations. Businesses that stick with outdated manual processes may find themselves struggling to keep up with competitors who have already made the switch to automated systems.

Why Automation Is the Smarter Move?

Automated Food Weighing and Packaging Equipment does more than just replace labor—it enhances your entire production line. With advanced sensors, precision weighing systems, as well as integrated packaging solutions, these machines deliver consistency and speed that no human workforce can match.

Here’s why food businesses are making the switch:

-

Accuracy You Can Rely On

Automation ensures every package meets exact weight requirements. No more guesswork, no more costly product giveaways.

-

Faster Output

Machines can operate continuously, handling high volumes of products with minimal downtime. This makes it easier to scale without hiring more staff.

-

Lower Long-Term Costs

While automation requires an upfront investment, the savings from reduced labor costs and minimized product waste add up quickly.

-

Regulatory Compliance

In the food industry, compliance is everything. Automated systems record and maintain accurate data, making audits and inspections much smoother.

How Automation Reduces Labor Dependency?

Think about how much time your team currently spends on tasks like:

- Manually weighing ingredients or portions.

- Checking for packaging errors.

- Re-packaging products due to inaccuracies.

With Automated Food Weighing and Packaging Machine, these tasks are completed quickly and consistently without the need for constant human oversight. Instead of hiring additional workers to meet seasonal demand or pushing your existing staff to work longer hours, automation allows your business to maintain production levels effortlessly.

This doesn’t mean eliminating staff altogether—it means reallocating their time to higher-value tasks, such as quality control, product development, or customer service.

The Role of Data and Technology

Modern automated weighing as well as packaging systems don’t just handle physical tasks—they also provide valuable data. From tracking production volumes to monitoring efficiency, these machines give food business owners actionable insights.

For instance, you can easily identify bottlenecks in the production line or see how much product waste has been reduced since implementing automation. With this kind of data, you’re not just improving efficiency—you’re making smarter business decisions.

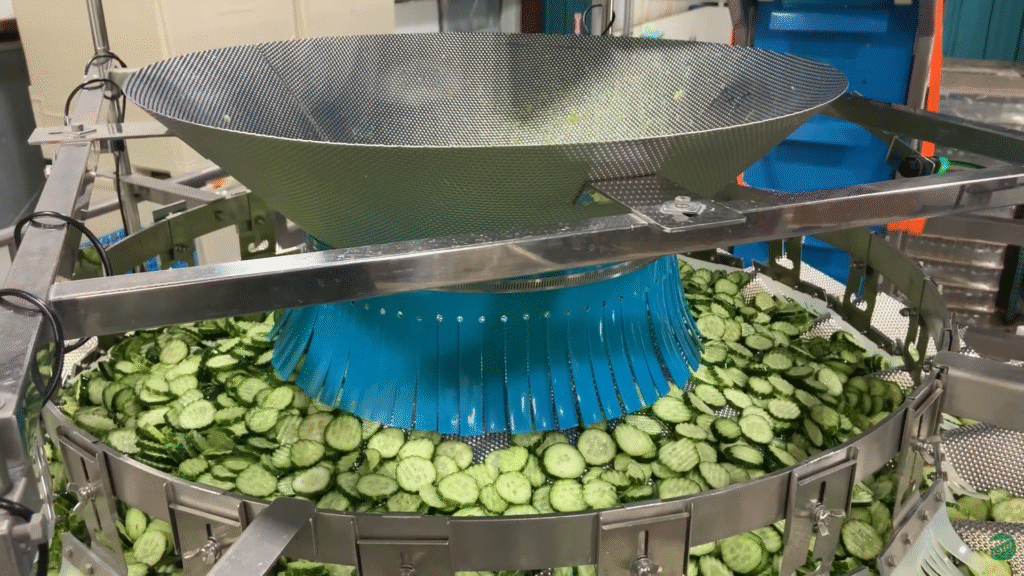

Real-World Applications

Automation isn’t one-size-fits-all. Whether you run a snack, bakery manufacturing facility, or a large-scale frozen foods business, there are solutions tailored to your needs.

-

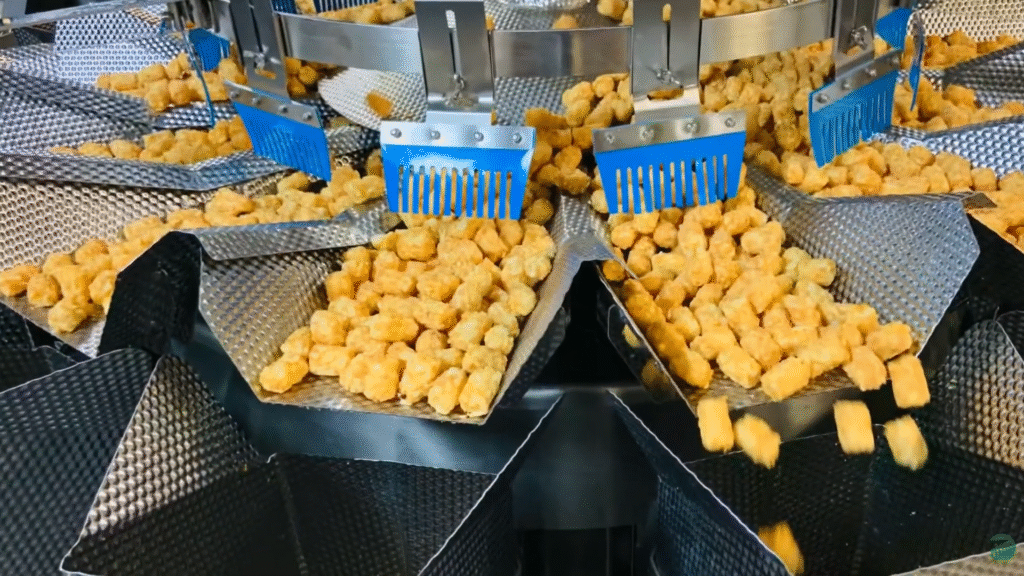

Snack Foods

Automated equipment ensures precise portion control, so every bag of chips or nuts has the exact same weight.

-

Meat & Poultry

Automated weighing systems reduce handling, which improves food safety and extends shelf life.

-

Bakery Products

From cookies to bread, consistent portioning ensures every product meets quality standards.

-

Frozen Foods

Automated systems handle packaging in cold environments where manual labor is less efficient and more costly.

Overcoming the Fear of Upfront Investment

It’s true that Automated Food Weighing and Packaging Equipment requires an initial financial investment. But many business owners find that the ROI comes faster than expected. By reducing labor costs, improving efficiency, and minimizing waste, automation pays for itself in a surprisingly short time. For any more information you can leave us a message here.

Think of it this way: every extra gram of product you give away in overfilled packages, and every hour of labor spent on repetitive tasks, costs you money. Automation eliminates those inefficiencies, helping you protect your margins.

Building a Future-Ready Food Business

Consumer demand for packaged food isn’t slowing down—it’s growing. At the same time, labor shortages are likely to continue being a challenge for food businesses across the country. By investing in automated weighing and packaging machine now, you’re future-proofing your business against these challenges.

Automation also strengthens your ability to adapt to market changes. Whether demand spikes during the holiday season or regulations become stricter, having reliable automated systems in place ensures your business can respond quickly and effectively.

Final Thoughts

The food industry is too competitive to rely on outdated, labor-intensive processes. Businesses that want to stay ahead need to embrace smarter, more efficient solutions. High Tek Automated Food Weighing and Packaging Equipment not only reduces dependency on labor but also improves accuracy, compliance, and overall profitability. By making the shift to automation, you’re not just cutting costs—you’re building a stronger, more resilient food business that’s ready for the future.